Direct-attached remote pressure transmitter

Measuring medium

Measure the pressure of liquids, gases, or vapors

Type of measurement

Gauge pressure measurement: Absolute pressure measurement

Output signal

4~20mA digital signal of HART protocol

RS485 serial signal

Measuring range

The compression ratio is recommended for the quantum code range

0C(0~4)KPa~40KPa 10:1

0E(0~2.5)KPa~250KPa 100:1

0F(0~10)KPa~1MPa 100:1

0G(0~30)KPa~3MPa 100:1

0H(0~0.1)MPa~10MPa 100:1

0I(0~0.21)MPa~21MPa 100:1

0J(0~0.4)MPa~40MPa 100:1

Level flange standard diameter min/max

journey

Longest capillary

Tube length

Flat type DN 50/2” 10kPa/10MPa 12m

DN 80/3’’ 6kPa/10MPa 16m

DN 100/4’’ 6kPa/3MPa 16m

Plug-in DN 50/2” 16kPa/10MPa 10m

DN 80/3’’ 6kPa/10MPa 16m

DN 100/4’’ 6kPa/3MPa 16m

Range limit

The minimum capacity of a monocrystalline silicon direct-coupled remote pressure/absolute pressure transmitter is the measuring range

The greater of the minimum range of the table and the flange table; The adjustable range must not be small

at the lowest scale.

The maximum range should be the maximum value of the transmitter body and the rated pressure of the remote flange

The minimum of the two.

Response time

The damping constant of the amplifier component is 0.1S, and the sensor and liquid level flange time are constant

The number is: (0.2~6)S, depending on the sensor range, range ratio, capillary size

The length of the tube, as well as the viscosity of the filling solution. Additional adjustable time constants

For: (0.1~60)S

Installation location impact

The intelligent remote pressure/absolute pressure transmitter without capillary can be transmitted remotely

The flange is mounted directly and the position deviation will produce a correctable zero offset.

The electronic case can be rotated up to 360° and the positioning thread holds it in place

What location. Remote pressure/absolute pressure flanges are fitted with ANSI/DIN compliant fittings

The flange is connected, and the matching flange should be equipped with a soft gasket and installed and fixed

bolts and nuts (users can choose to install bolts and nuts). For the band

Capillary intelligent remote pressure/absolute pressure transmitter, if remote sealed device

Lower than the transmitter body, the remote transmission sealing device and the transmitter body are the largest

The height drop should be <5m, when the working pressure is lower than 100kPa absolute pressure,

The transmitter body must be lower than the remote sealing device. Minimal bending of the capillary

The radius is 75mm, and winding is strictly prohibited!

Ambient temperature

The minimum depends on the filling fluid

Up to 85°C

-20~65°C with display and fluoroelastomer seal

Storage temperature

The minimum depends on the filling fluid

Up to 85°C

The temperature limit of the process medium is -30~400°C

relative humidity

(

Menu

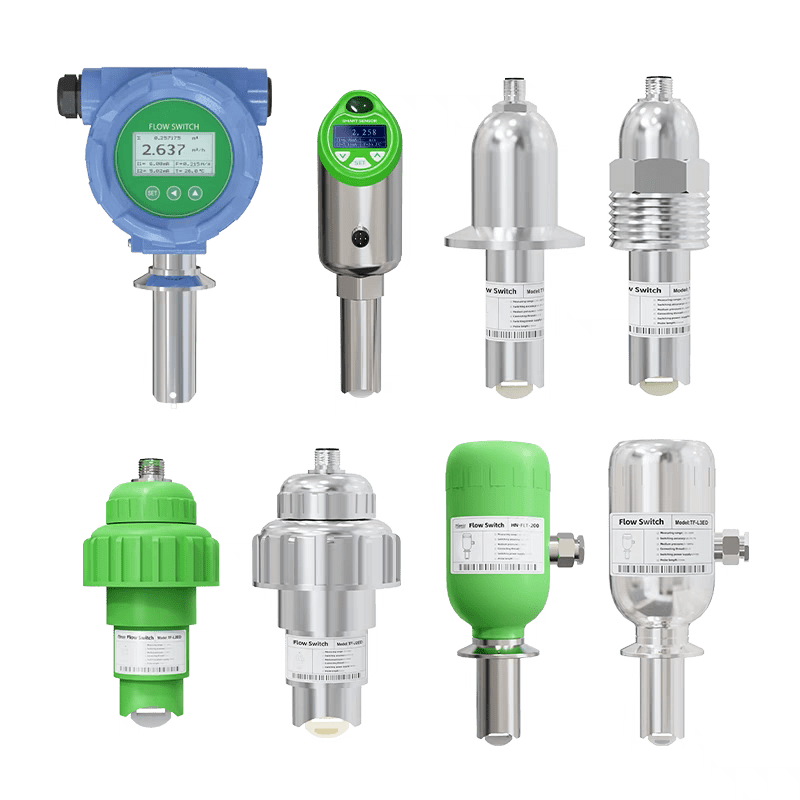

New Product

There is a solution for every application. Let’s work together to find the right solution for you.

Your benefits

We use our experience to move your project forward.

PHONE: 400-8868-261

E-mail: info@kielplanckprc.com / kielplanck@outlook.com