| Applicable media | Medicines, food, milk, beer, beverages, juices… |

| Measuring range | -1-4MPa |

| Turndown ratio | 1:100 |

| measurement accuracy | ±0.075%FS, ±0.1%FS, ±0.2%FS, ±0.5%FS |

| stability | Up to ±0.10% of upper range limit (URL), 60 months |

| pressure type | Gauge pressure, absolute pressure, negative pressure, high static pressure, micro pressure |

| show | LED on-site display |

| menu adjustment | Adjustment via Hart Communicator |

| input voltage | 12-36V DC |

| output | 4-20mA, RS485, Hart, etc. |

| Operating temperature | -35-125°C |

| Overload pressure | 150%FS |

| bursting pressure | 300%FS |

| error alarm | Self-diagnostic program detects fault, analog output is higher than 20.8mA or lower than 3.8mA, alarm, high/low flag is adjusted by HART communication |

| ambient temperature | -40-80℃ |

| response time | <1ms (10…90%FS) |

| refresh time | 0.25S |

| service life | >1*10^8 pressure cycles |

| Liquid contact material | Stainless Steel 316L, Hastelloy C, Monel, Tantalum |

| shell material | stainless steel |

| Protection class | Electrical part IP67 (optional IP68) |

| Electrical connections | Aviation plug |

| electrical protection | Overload/Reverse Phase Protection |

| Explosion proof | Intrinsically Safe ExiaIICT4 |

| sealing material | Silica gel |

| Installation method | Chucks, clamps |

| weight | Approx. 1.4kg |

Menu

New Product

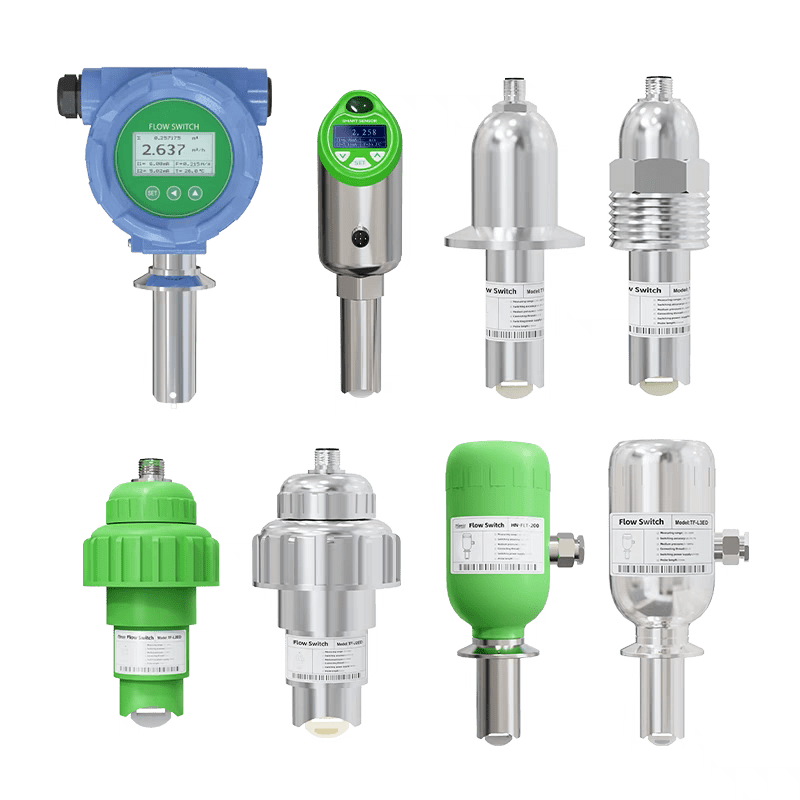

There is a solution for every application. Let’s work together to find the right solution for you.

Your benefits

We use our experience to move your project forward.

PHONE: 400-8868-261

E-mail: info@kielplanckprc.com / kielplanck@outlook.com