| Implementation standards | Electromagnetic flowmeter (JB/T 9248-2015) |

| Suitable medium | Acid, alkali, salt solution, water, sewage, corrosive liquid and mud, pulp, pulp and other conductive liquid, solid-liquid two-phase |

|

Nominal Meridians (mm) Special specifications can be customized |

Tube type teflon lining: DN15-DN2000 |

| Pipeline rubber lining: DN65-DN2000 | |

| Tubular F46 lining: DN4-DN600 | |

| Direction of flow | Positive, negative, net flow |

| Range ratio | 150:1 |

| Repeatability error | ± 0.1% of the measured value |

| Accuracy Level | 0.5,1.0 |

| The temperature of the measured medium | Conventional rubber lining: -20 ~ + 60 ° C |

| High temperature rubber lining: -20 ~ + 90 ° C | |

| Polytetrafluoroethylene lining: -30 â ° â ° + 120 â ° C | |

| High temperature tetrafluorin linings: -20 ~ + 160 ° C | |

| Rated working pressure (high pressure can be customized) | DN15ー DN25≤4.0 MPa |

| DN32ー DN300≤1.6 MPa | |

| DN350ー DN800≤1.0 MPa | |

| DN800ー DN2000≤0.6 MPa | |

| Velocity Range | 0.1-15m/s |

| Electrical conductivity range | The conductivity of the measured fluid is more than 20 μs/cm |

| Signal output | 4-20mA (load resistance 0-750ω) , pulse/frequency |

| Communication output | RS485, Modbus protocol, GPRS output |

| Power supply | 220VAC, tolerance 15% or 24VDC, ripple ≤5% |

| Straight pipe section length is required | Upstream ≥5 dn, downstream ≥3 dn, installation conditions affect the requirements of straight pipe section |

| Connection mode | Flanged connection is adopted between flowmeter and piping. Flanged connection conforms to international standard: GB/T9119 -2000 |

| Protection level | IP67 |

| Ambient temperature | -25~+60℃ |

| Relative humidity | 5%~95% |

| Consumption of total power | Less than 7.5 W |

Menu

New Product

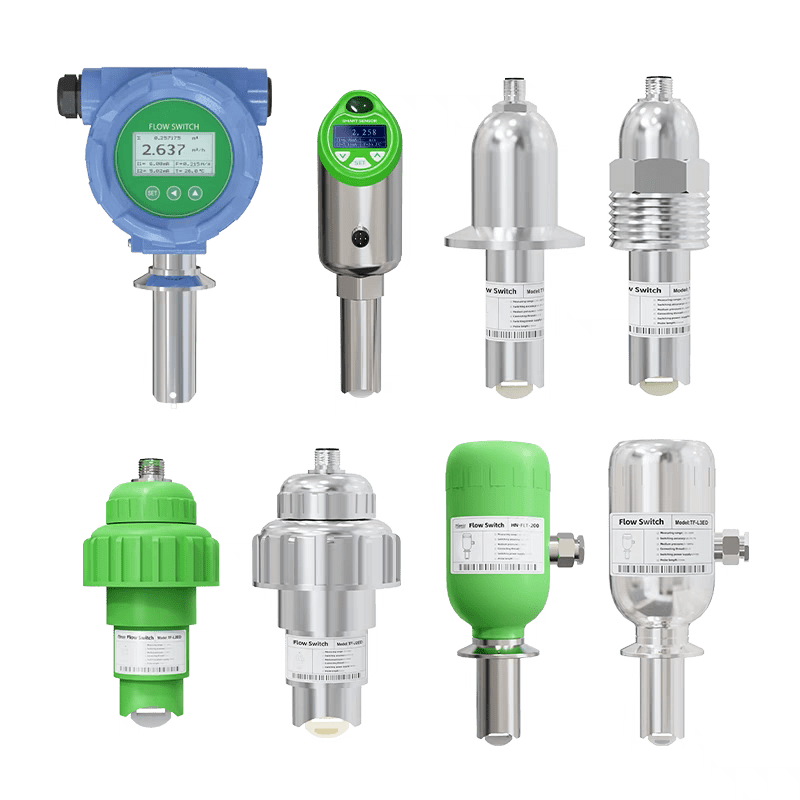

There is a solution for every application. Let’s work together to find the right solution for you.

Your benefits

We use our experience to move your project forward.

PHONE: 400-8868-261

E-mail: info@kielplanckprc.com / kielplanck@outlook.com