Technical parameters

– Flowmeter diameter: DN15, DN25, DN50, DN80, DN100, DN150 (other diameters please consult with the manufacturer)

– Flow Range: Liquid: 1.0 – 150000L/h; Gas: 0.05 – 3000m³/h (see flow table on page 11 for flow range)

– Turndown ratio: 10 : 1, 20 : 1 (special)

– Accuracy: Class 1.5, Class 1.0 (Special)

– Pressure rating: DN15, DN25, DN50: 4.0MPa (max;D. 20MPa), N80, DN100, DN150: 1.6MPa (Max: DN80: 10MPa; DN100: 6.4MPa, DN150: 4.0MPa)

– Medium temperature: standard: -30°C – 120°C, high temperature: 120°C – 350°C; PTFE liners should not be higher than 80°C

– Power supply: 24VDC (12 – 36VDC), lithium battery powered, 220VAC

– Output Signal: 2-Wire: 4 – 20mADC HART protocol; Three-wire system: MODBUS (RTU mode); Cumulative pulse (24V, 50% duty cycle); Optional relay alarm, electric shock melt 250VAC 3A

– Output Load: 500Ω (at 24VDC power supply)

– Ambient temperature: -40°C – 120°C; Remote type: -30°C – 70°C

– Storage conditions: Temperature: -40°C – 85°C; Humidity: ≤85%

– Connection: Standard type: flange standard GB/T9119-2000, user can specify; Food type: clamp connection method; Special type: designed according to user requirements

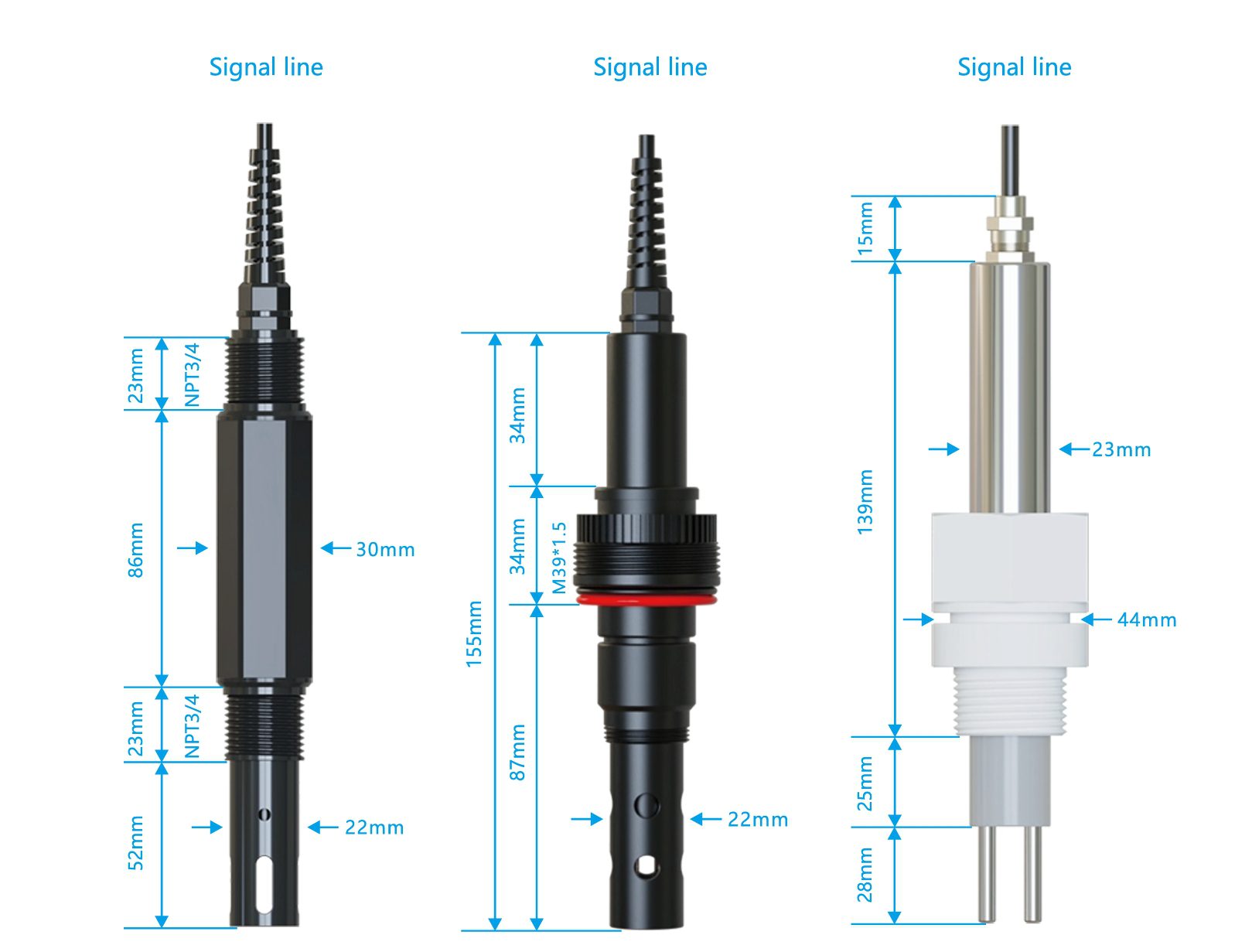

– Cable interface: M20×1.5, 1/2NPT

– Enclosure protection: IP65

– Explosion-proof marking: Intrinsically safe type: Exia II CT6Ga, flameproof type: Exd II CT6Gb

– Media viscosity: DN15: η<5 mPa.s, DN25: η<250 mPa.S, DN50 – DN150: η<300 mPa.S

– Measuring tube and float material: Rl:304,0Cr18Ni9; Ro:316,0Cr18Ni12Mo2Ti; Rl:316L,00Cr17Ni14Mo2Ti; H: Hastelloy B, Hastelloy C; Ti: titanium, titanium alloy; RP: PTFE lining

– Hygienic: Surface finish< 0.8Ra